We offer the following PLC trainings:

Controbyte

Controbyte

ABOUT US

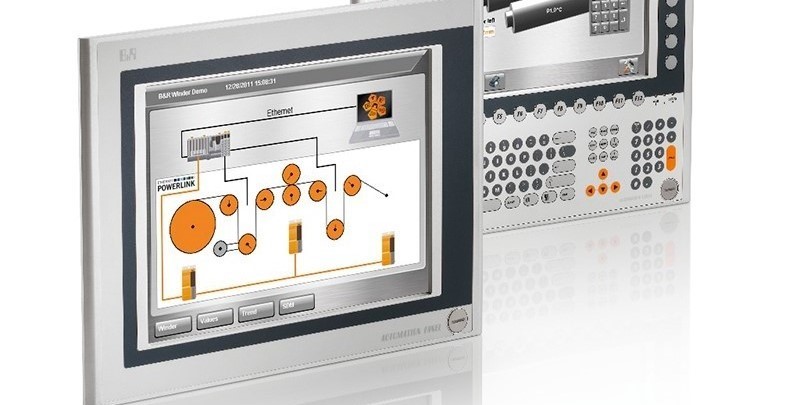

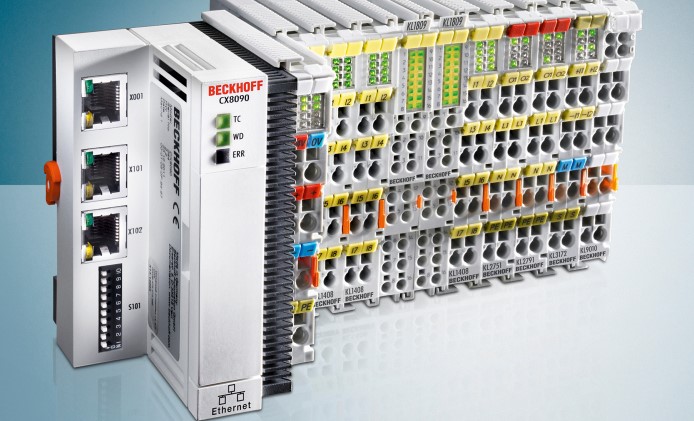

Controbyte is a highly specialized industrial automation technology specialist. With extensive expertise and a wealth of experience in this field, Controbyte offers comprehensive solutions for all your industrial automation needs. Our services include a wide variety of offerings, including state-of-the-art hardware-related PLC training and customized individual automation engineering solutions. We pride ourselves on delivering state-of-the-art solutions that optimize our customers' productivity, efficiency and overall operational performance. We excel in programming a wide range of control systems, including Siemens, B&R and Beckhoff.

AUTOMATION SOLUTIONS

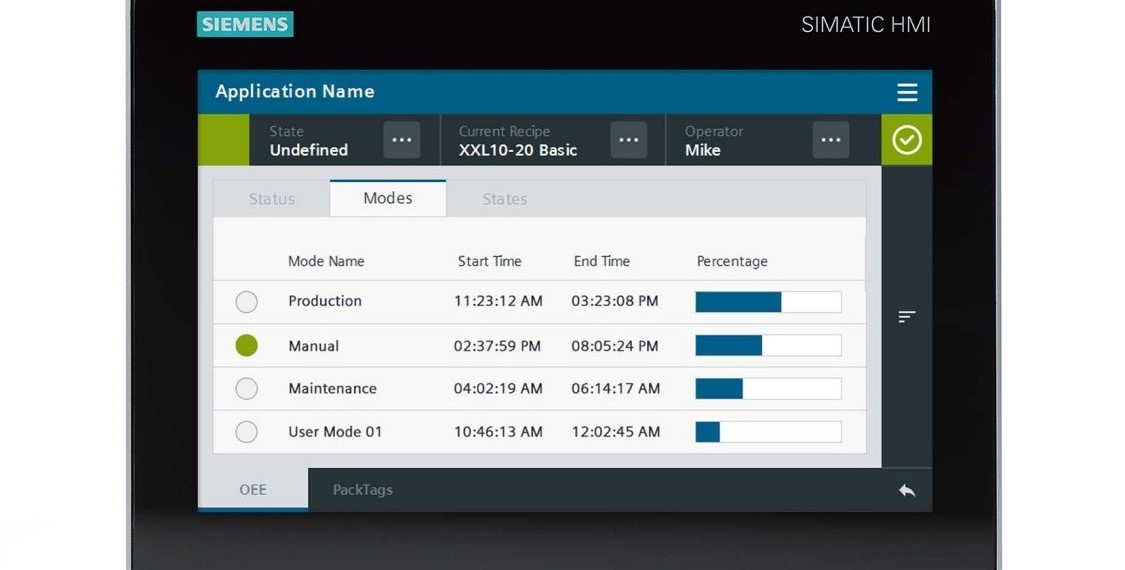

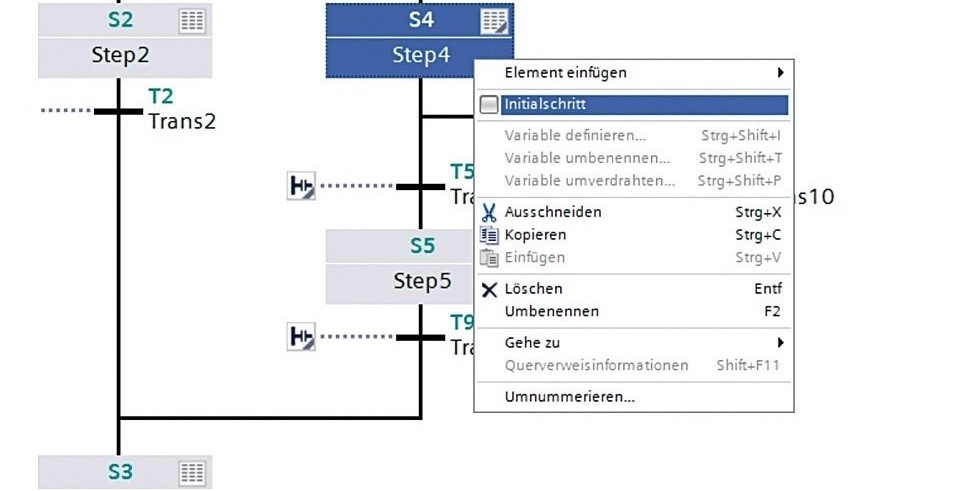

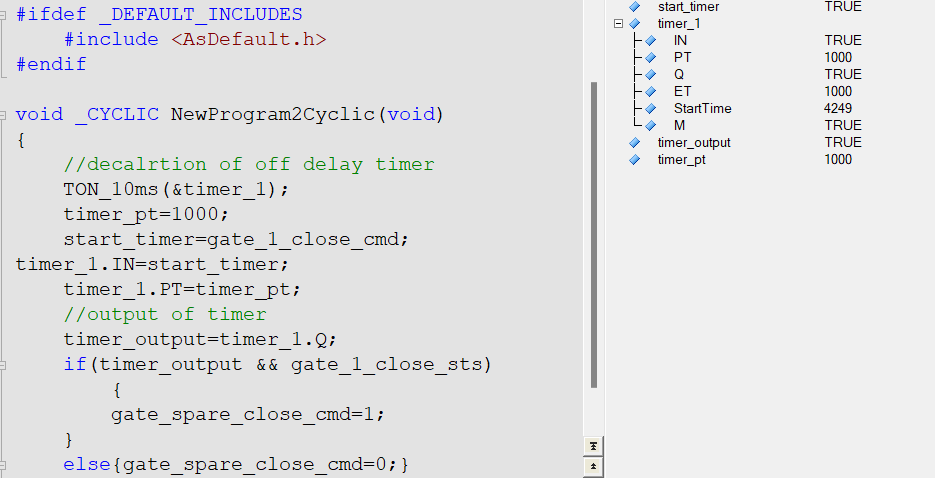

Due to our extensive industrial partnerships, we have profound know-how in automation technology. We specialize in the development of PLC programs for a wide range of industrial applications and can thus carry out complex projects efficiently, sustainably and with minimal error rates. In special machine construction, the visualization and programming of complex machine controls is one of our daily tasks. Our service promise goes beyond mere provision, because we accompany you on your way to industrial automation. From the initial conception and design of customized automation solutions to the final implementation, installation and commissioning of diverse machines and systems, we offer you comprehensive support.

OUR PLC TRAININGS

At Controbyte, our PLC training is designed to closely link theory and practice, creating a seamless connection to the hardware. We use training objects such as models from Fischer-Technik that are connected to the controllers. This hands-on training style ensures an intensive learning experience and enables participants to effectively bridge the gap between theoretical knowledge and practical application. We offer comprehensive training for various software systems, including Simatic TIA Portal and Simatic PCS 7 from Siemens, Automation Studio from B&R and Twincat 3 from Beckhoff.